Could deep learning and computer vision be used to automate the inspection of the omni-present energy labels? You bet!

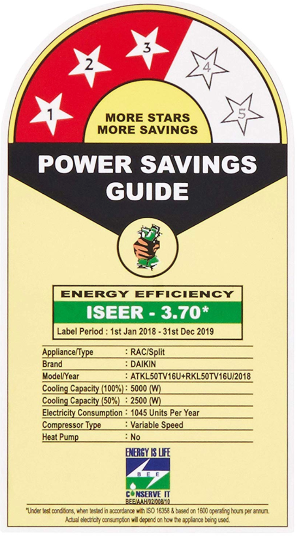

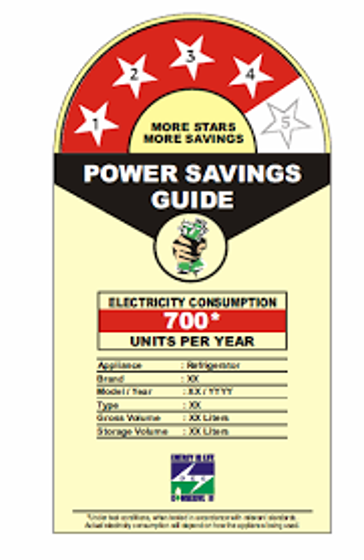

Energy labels on appliances such as washing machines, refrigerators, and air conditioners are crucial in helping consumers make energy efficient choices. For example, “Star Labels” from India’s Bureau of Energy Efficiency (BEE) can provide a plethora of information on a gadget’s energy consumption and comparative standing among its peers in efficiency. This is in addition to standard specifications like type, brand, model, and year of manufacture.

The compliance requirements for these labels can change depending on the type of appliance. For example, a label on a Split AC (below left) which is used intermittently shows its energy efficiency as an ISEER rating. But a label on a refrigerator which runs throughout (below right) shows its energy consumption per year.

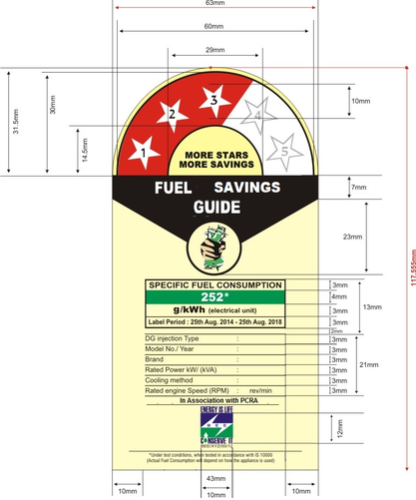

Additionally, there are requirements on label aesthetics and formatting including font size, graphics arrangement, and even spacing between lines as per BEE guidelines below.

Consumer electronics manufacturers who make multiple appliances can run into trouble verifying compliance of energy labels, even when relying on machine vision software and automation set ups. Developing computer vision algorithms for individual labels can be time consuming and prone to errors given the wide variety of information to be captured on different labels. On top of that, label requirements may change from time to time, requiring frequent software updates.

Keeping these challenges in mind, Add Innovations has developed a unique deep-learning based inspection system which can verify compliance for multiple labels and appliances. The system can “learn” the characteristics of the specific label it needs to check using a training set of labels. Once training is complete, it can inspect live specimen on a production line without the need for any user-defined criteria. In other words, the user does not need to tell the system the correct font size, line spacing, energy rating, or even the type of appliance. The system “learns” is all from the training set. A different training set, means a different label can be inspected. As simple as that.

Oh, and it can check a label for compliance – for everything from content, print defects, stains or foreign objects, aperture location and size, or print shifting in a fraction of a second. Giving fully compliant labels, satisfied regulators, and energy conscious consumers.

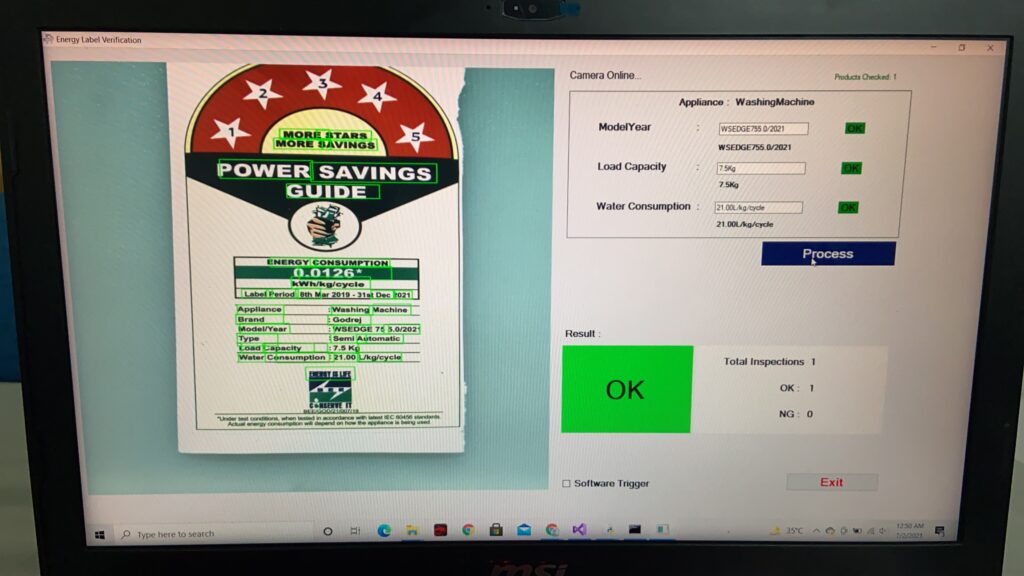

Here is Add Innovations’ deep-learning based system in action on an actual production line.