Since 1960, The Jaquar Group has established themselves as the marquee luxury brand in faucet and the larger sanitary-ware category. Their reputation is based on innovative designs, award-winning customer support, and most importantly, an obsessive focus on high quality products, able to compete with the best international brands.

Key to their quality control is inspecting each faucet specimen for a variety of visual defects, including:

- Blemishes

- Dents

- Porosity

- Cracks

- Scratches

- Grinding Lines

- Bufflines

- Presence of foreign particles.

Manually inspecting specimens for these defects was a highly time-consuming process with potential for human error, and reputational risk.

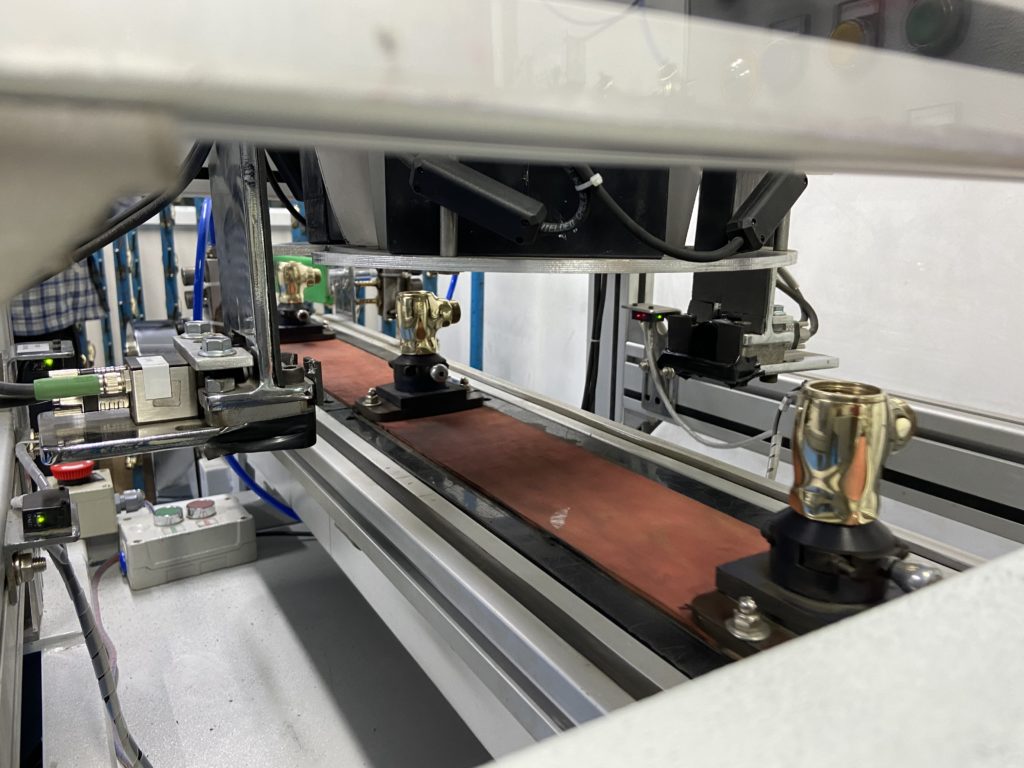

Enter Add Innovations. With our core competency in building high quality, customized machine vision systems, Add Innovations worked with the technical team at Jaquar to build an automated quality inspections system to check for their above blemishes.

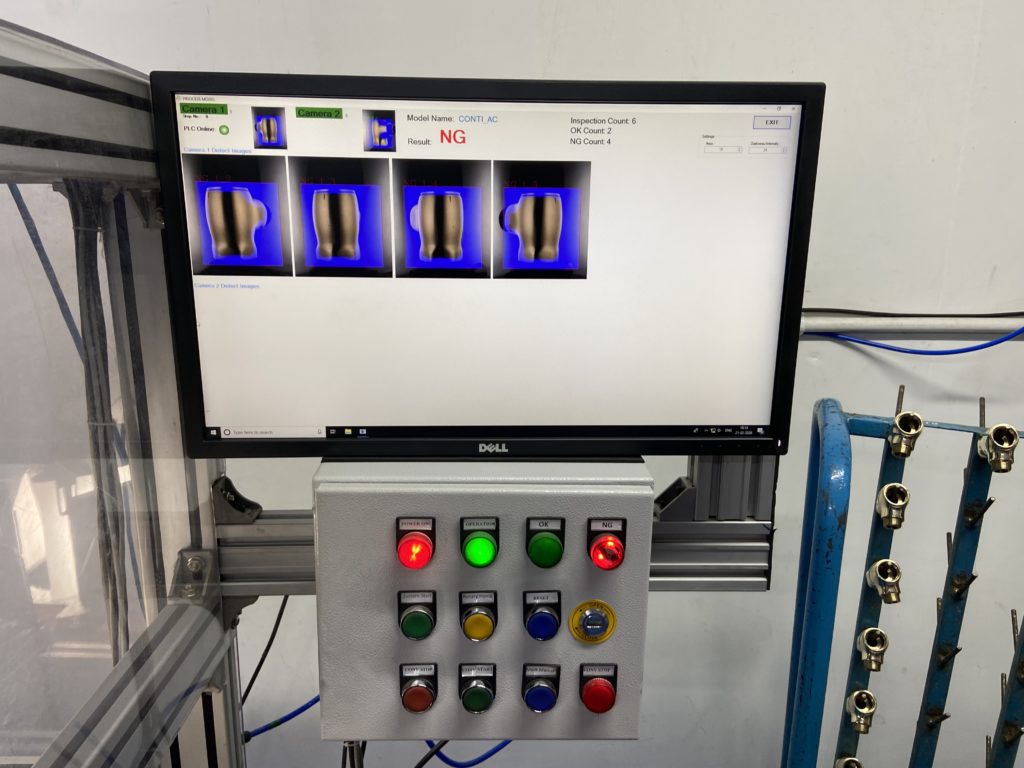

Combining two industrial grade machine vision cameras (Baumer), with specialized lenses (VST), and two vision system lights with customized diffusion mechanism, the machine vision system is robust, effective, and stand-alone.

As always, our system runs on custom built, lightweight, and user-friendly PC-based software by Add Innovations.

The system is running at full capacity at Jaquar’s Bhiwadi plant, reducing errors, and exponentially speeding up the inspections process. Watch the system in action in the video below: